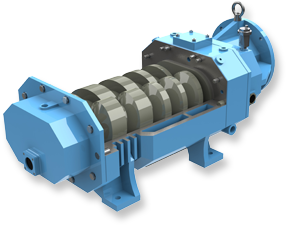

WIN Dry Screw Vacuum Pump

- Oil free Dry Vacuum Pump

- Variable Pitch Screw

- Pumping Capacity 100~1500 m3/hr

- Ultimate 0.0075 torr Vacuum degree

- Excellent Corrosion Resistance

- Superior Liquid and Dust handling ability

- No Effluent, No Pollution, No Waste

- Lower Maintenance Costs

- Lower Power & Utilities Consumption

Technical Data

| Model | WIN150 | WIN300 | WIN400 | WIN800 | WIN1500 | |

|---|---|---|---|---|---|---|

| Displacement (50/60Hz) |

m3/hr | 110 / 130 | 250 / 300 | 330 / 400 | 660 / 800 | 1250 / 1500 |

| Ultimate pressure | torr | 0.05 | 0.0075 | 0.0075 | 0.0075 | 0.0075 |

| Motor power (50/60Hz) |

kW | 3.7 / 3.7 | 7.5/7.5 | 11/11 | 15/15 | 37/37 |

| Rotation (50Hz/60Hz) |

rpm | 2,950 / 3,550 | ||||

| Process Connection | ||||||

| Inlet Connection | Special | 1 ½” (40A) | 2” (50A) | 2 ½” (65A) | 4” (100A) | 5” (125A) |

| Outlet Connection | Special | 1 ½” (40A) | 1 ½” (40A) | 2” (50A) | 2 ½” (65A) | 3” (80A) |

| Cooling water | ||||||

| Max. Supply Pressure | Barg | 7 | 7 | 7 | 7 | 7 |

| Pressure Drop | Bar | 1 | 1 | 1 | 1 | 1 |

| Flow Rate | L/min | 5~10 | 10~15 | 10~15 | 15~20 | 36~40 |

| Temperature | ℃ | 5~35 | 5~35 | 5~35 | 5~35 | 5~35 |

| Connection | PT(JIS) | ½”(15A) | ½”(15A) | ½”(15A) | ½”(15A) | 1”(25A) |

| Lubricant | ||||||

| Gear & FEP Bearing | Shell T-68 | Shell T-68 | Shell T-68 | Shell T-68 | Shell T-68 | |

| REP Bearing | Mobil 1 | Shell T-68 | Shell T-68 | Shell T-68 | Mobil 1 | |

| Noise Level (50/60Hz) |

dB | 80 / 85 | 80 / 85 | 82 / 85 | 82 / 85 | 82 / 85 |

| Vibration (max.) | mm/s | 1.8 (4.5) | 1.8 (4.5) | 1.8 (4.5) | 2.8 (4.5) | 2.8 (4.5) |

| Weight (Bare Shaft) |

kg | 200 | 300 | 400 | 600 | 900 |

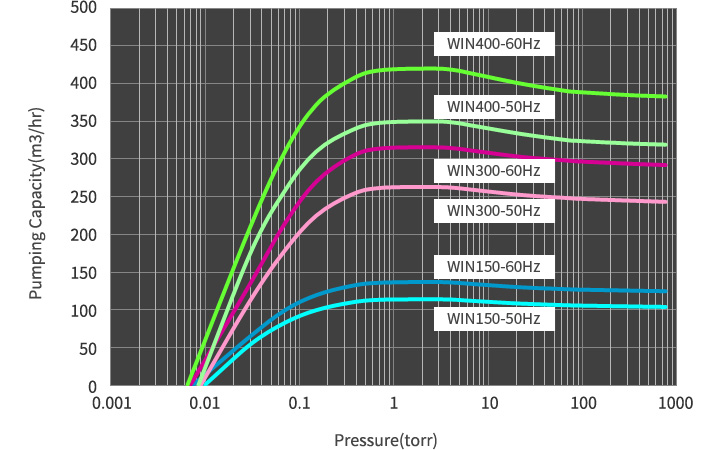

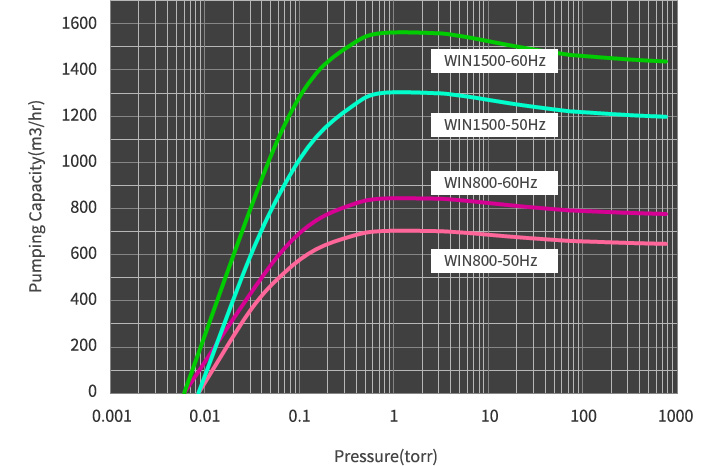

Pumping Speed

Material

| Materials of House | |

|---|---|

| Casing | Ductile Iron(FCD 400), Internal Coating |

| Screws | Ductile Iron(FCD 400), External Coating |

| Front End Plate | Ductile Iron(FCD 400), Internal Coating |

| Front End Cover | Ductile Iron(FCD 400) |

| Rear End Plate | Ductile Iron(FCD 400) |

| Check Valve | Stainless steel body + Teflon Seat |

| Coatings | PTFE Coating : 20µm Thickness |

| PFA Coating : 40µm Thickness | |

| PEEK Coating : 20µm Thickness | |

| NIFA (Nickel Plated + Teflon Coating) | |

| PeeFLON (PEEK + PFA modified + PFA) | |

| Niflor (autocatalytic composite coating nickel-PTFE) | |

| Seal Material | |

| Lip Seal | PTFE & Graphite(or Polyamide) Mix in Stainless Steel |

| Mechanical Seal | Rotor : Stainless Steel Bellows with Carbon #5 Face |

| Stator : Stainless Steel with Tungsten Carbide Coating | |

| O-ring : Viton or Kalrez | |

| Oil Seal | Viton |

| Seal Arrangement | |

| HV(Suction) | Lip Seals(Single Lip Seal x 3ea) |

| LV(Discharge) | Lip Seal & Mechanical Seal + Gas Purge Seal |

| Drive End | Oil Seal |

| Bearings | |

| HV(Suction) | Roller Bearing |

| LV(Discharge) | Angular Double Ball Bearing |

| Drive End | Single Ball Bearing |

| Lubricant | |

| Gear Box | Shell Turbo Oil T68 |

| Rear end bearing | Shell Turbo Oil T68 or Mobil 1 Synthetic Grease |